Proactive and Predictive Maintenance & Service Readiness

Stay confident every day of the year!

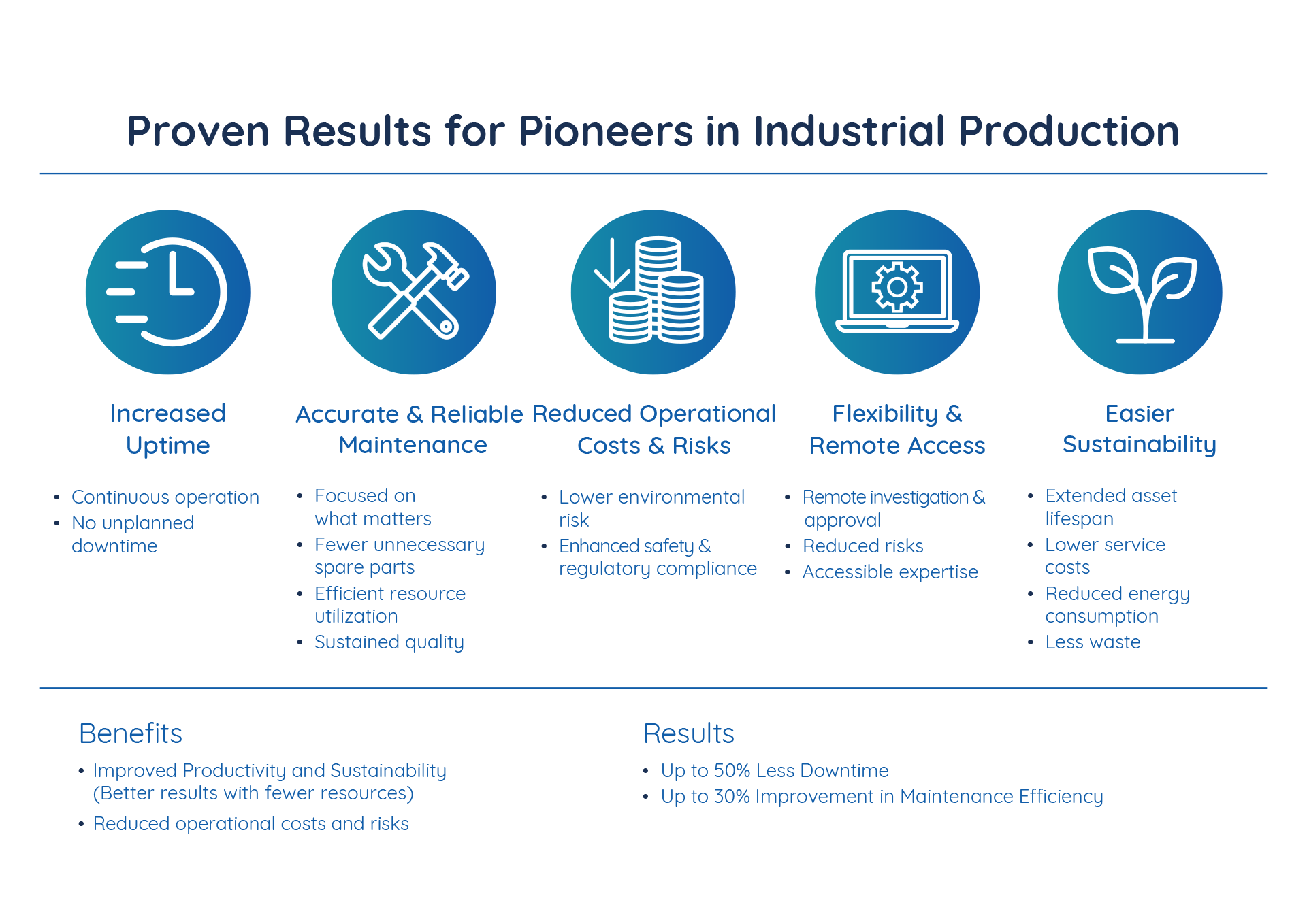

Reduced Downtime:

By identifying and addressing potential issues, proactive maintenance minimizes unexpected stoppages, ensuring continuous production.

Extended Equipment Lifespan:

Regular maintenance extends the lifespan of machines and equipment, reducing the frequency of replacements and associated costs.

Cost Savings:

Predictive maintenance helps avoid expensive emergency repairs and production losses, leading to significant cost savings.

Enhanced Safety:

Regular inspections and maintenance ensure machines operate safely, reducing the risk of injuries.

Increased Efficiency:

Well-maintained equipment operates more efficiently, resulting in better productivity and optimized energy consumption.

Improved Planning and Resource Allocation:

A well-designed maintenance plan allows for optimized use of workforce, spare parts, and maintenance scheduling, enhancing resource utilization.

Data-Driven Decision Making:

Proactive maintenance involves data collection and analysis, enabling informed decisions to prioritize improvements.

Compliance and Quality Assurance:

Regular maintenance ensures adherence to industry regulations and standards, contributing to product quality and regulatory compliance.

On-Call Service

• 24/7 availability every day of the year

Service Readiness

• Programmer engineer and technician support

• Fault detection within 8 hours

• Immediate start of troubleshooting upon detection

Prediction

• AI-based prediction of potential faults

• Estimated lifespan forecasting for equipment

Regular Maintenance

• Machines and production equipment

• Electrical networks

• Software, PLCs, and other controls

Documentation

• Maintenance logging

• Backup management

Support

• Dedicated contact person

• Proactive consultancy

For production-related PGs or other PCs:

• CPU Temperature Check

• Re-pasting of Cooling Fins (if necessary)

• Hard Drive Analysis (checking for saturation and fragmentation)

• Memory Diagnostics

• Internal Dust Removal (inside the casing)

• Fan Performance Check Status Verification of Updates

For PLC Controllers:

• Creating an instantaneous backup of the controlled device in a powered-down state

• Archiving the saved data by machine number (retrievable and restorable at any time)

• Reading the error log (if supported by the configuration)

• Assessing the age and expected lifecycle of the devices

For Machines and Equipment:

• Inspection, lubrication, and replacement of wear parts

• Examination of mechanical components; repair and refurbishment of rotating, cutting, grinding, and pressing elements

For Electrical Switch Cabinets:

• Inspection of electrical connections

• Checking and tightening terminals

• Internal dust removal of the cabinet

• Instrumental testing of the BUS network

For Electrical Networks and Field Devices:

• Inspection of accessible connections

• Tightening terminals

• Visual inspection of wiring consistency

• Instrumental testing of the BUS network

Assessment

• Understanding values and benefits

• Reviewing goals and risks

• Planning & resource allocation

• Creating a project plan

Planning

• Selection of included equipment

• Identification of failure modes and related data

• Definition of predictive maintenance steps

• System and data traffic planning

Implementation

• Installation of predictive maintenance software, data collection, and storage

• Data processing and transmission

• System configuration and tuning

• Setting up indicators and alerts

Operation

• Monitoring

• Maintenance

• Ad-hoc investigations

• Periodic reviews

Development

• Improving data accuracy and integrity

• Fine-tuning of predictive maintenance software

• Identifying further development opportunities

• Enhancing processes and integration

Call our colleagues, who are ready to assist you!

+36 20 548 1181

Write to us!